In today’s refrigeration market, you face a pressing problem: condensation, fogging and inconsistent glass‑door performance are hurting your display units — increasing maintenance costs, damaging your brand image, and delaying production. At the same time, you’re under pressure to meet tight delivery deadlines and control costs. We understand your frustration.

As a factory specialising in electrically heated glass doors, we stand ready to solve that problem for you — delivering customised, high‑quality solutions on time, with full technical support and streamlined production.

Let’s keep going — you’ll see why partnering with the right electrically heated glass door manufacturer matters, what to look for, and how we help you win.

Table of Contents

What is Electrically Heated Glass Doors?

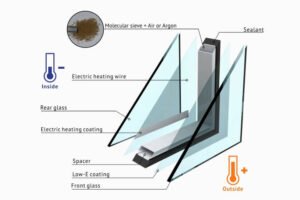

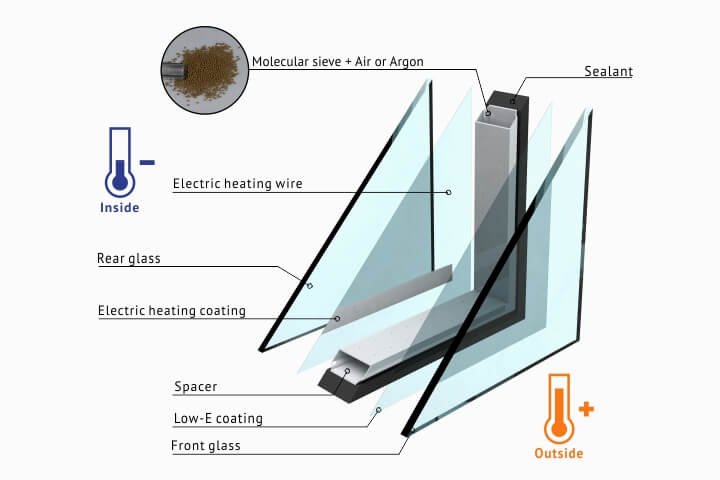

Electrically heated glass doors are refrigeration or freezer doors whose glass panes include a conductive coating or embedded heating element. When powered, the glass warms slightly above the dew point to prevent condensation, fogging or frost on the surface.

How do Electrically Heated Glasses Work to Prevent Condensation on Refrigeration Equipment?

The glass includes a transparent conductive layer or embedded film. When current flows, the glass surface warms, raising its temperature just enough so the surface stays above the dew point and moisture does not condense.

6 Benefits of Our Electrically Heated Glass Doors

Let’s take a closer look at why our glass doors are trusted worldwide — and how they give your refrigeration systems a real competitive edge.

-

Anti-Fog & Anti-Frost Performance

Our advanced heating technology automatically prevents condensation and frost buildup caused by temperature differences — ensuring clear, uninterrupted visibility in all environments, from chilled display units to deep freezers. -

Energy Efficiency That Pays Off

Integrated smart control systems regulate heating based on humidity and temperature. This ensures the heater only operates when necessary — reducing energy waste while maintaining high-performance visibility. -

Enhanced Product Display for Retail Impact

Clear glass means your products stay visible at all times — increasing shopper engagement. Combined with our sleek, modern design, our doors elevate the professional appearance of your retail space or showcase environment. -

Durability & Safety Built In

We use high-quality tempered or laminated glass, offering excellent impact resistance and safety. For high-traffic areas, optional explosion-proof models are available, ensuring maximum reliability and protection. -

User-Friendly & Smart Features

Functions like one-touch defogging provide manual override when needed, while integration with freezer control systems allows for automated performance monitoring — making operation seamless for your team. -

Broad Application Across Industries

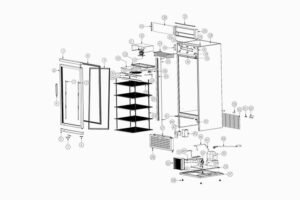

Our glass doors are ideal for supermarket display freezers, ice cream cabinets, medical fridges, and walk-in coolers. Wherever you need clear visibility and stable cold storage, our solutions fit.

How to Choose a Right Electrically Heated Glass Door?

Selecting the correct electrically heated glass door involves evaluation of environment, cooling system, and technical compatibility. Here are the key factors you must verify before specifying and ordering — because your downstream production, installation and maintenance costs depend on it.

Specifications of the Tested Glass Door:

Dimenisons: W=556mm H=1636mm

PVC door frame, double layer hollow glass, inner glass is with low-E, and the argon gas displacement in the hollow layer is not less than 93%.

The temperature inside the cabinet is M1 level (-1.5) ℃

| Environmental Conditions | Theoretical Dew Point | Glass Heating | Frame Heating | ||

|---|---|---|---|---|---|

| Level | Ambient Temperature | Ambient Humidity | Temperature Value | Experience Value | Experience Value |

| 3 | 25℃ | 60RH% | 16.7℃ | — | — |

| 26℃ | 60RH% | 17.6℃ | — | — | |

| 4 | 30℃ | 55RH% | 20.0℃ | — | — |

| 27℃ | 70RH% | 21.1℃ | — | — | |

| 5 | 40℃ | 40RH% | 23.5℃ | — | — |

| 28℃ | 70RH% | 25.1℃ | — | — | |

| 30℃ | 75RH% | 26.2℃ | — | — | |

| 7 | 35℃ | 75RH% | 30.0℃ | <50W | — |

| 34℃ | 75RH% | 32.1℃ | <50W | — | |

| 36℃ | 85RH% | 34.1℃ | <70W | <35W | |

The temperature inside the cabinet is L3 level(-15,-10)℃

| Environmental Conditions | Theoretical Dew Point | Glass Heating | Frame Heating | ||

|---|---|---|---|---|---|

| Level | Ambient Temperature | Ambient Humidity | Temperature Value | Experience Value | Experience Value |

| 3 | 25℃ | 60RH% | 16.7℃ | =<40W | — |

| 26℃ | 60RH% | 17.6℃ | =<40W | — | |

| 4 | 30℃ | 55RH% | 20.0℃ | =<50W | — |

| 27℃ | 70RH% | 21.1℃ | =<50W | — | |

| 5 | 40℃ | 40RH% | 23.5℃ | =<75W | =<35W |

| 28℃ | 70RH% | 25.1℃ | =<75W | =<35W | |

| 30℃ | 75RH% | 26.2℃ | =<75W | =<35W | |

| 7 | 35℃ | 75RH% | 30.0℃ | =<100W | =<35W |

| 34℃ | 75RH% | 32.1℃ | =<100W | =<35W | |

| 36℃ | 85RH% | 34.1℃ | =<130W | =<54W | |

The temperature inside the cabinet is F level(-24,-18)℃

| Environmental Conditions | Theoretical Dew Point | Glass Heating | Frame Heating | ||

|---|---|---|---|---|---|

| Level | Ambient Temperature | Ambient Humidity | Temperature Value | Experience Value | Experience Value |

| 3 | 25℃ | 60RH% | 16.7℃ | =<70W | =<35W |

| 26℃ | 60RH% | 17.6℃ | =<70W | =<35W | |

| 4 | 30℃ | 55RH% | 20.0℃ | =<95W | =<35W |

| 27℃ | 70RH% | 21.1℃ | =<95W | =<35W | |

| 5 | 40℃ | 40RH% | 23.5℃ | =<110W | =<54W |

| 28℃ | 70RH% | 25.1℃ | =<110W | =<54W | |

| 30℃ | 75RH% | 26.2℃ | =<135W | =<54W | |

| 7 | 35℃ | 75RH% | 30.0℃ | =<135W | =<54W |

| 34℃ | 75RH% | 32.1℃ | =<150W | =<54W | |

| 36℃ | 85RH% | 34.1℃ | =<150W | =<54W | |

Why PARTSAY

What Makes Our Heated Glass Doors Stand Out

-

Complete Heating Strategy: Glass + Frame Heating

We understand real-world environments. That’s why we offer both glass and optional frame heating for extreme humidity or harsh climates. This eliminates fogging not just on the pane, but around edges where condensation most often forms. -

High-Performance Insulation System

Our doors are built with double-glazed low-E glass and >93% argon fill in the hollow layer — reducing heat transfer, maintaining thermal stability, and lowering heater energy demand. -

Compliance You Can Trust

We exceed global standards with third-party test certifications:

EN-1279-2: Moisture Penetration

EN-1279-3: Argon Concentration

Fragmentation & Impact Safety Standards This means verified durability, thermal performance, and safety. -

Smart System Integration

Our technology supports smart sensors, humidity-triggered heating, and one-touch defogging. It reduces energy consumption, simplifies maintenance, and enables advanced system-level integration. -

Installation Support & Retrofitting Compatibility

From wiring diagrams to frame design guidance, we ensure smooth integration into your systems — including retrofits, with full tech support and no surprises. -

Reliable Lifecycle & Service Plan

Our doors offer a 15+ year seal integrity guarantee and we provide all necessary replacement parts and documents for long-term use. Technical team assistance is available worldwide. -

Strong ROI Case

You save on labor (no manual defogging), reduce spoilage, cut compressor runtime, and improve product presentation. That’s a clear return on investment that grows your bottom line.

Get A Quote

Let’s move from theory to action. To provide you with an accurate quote from our factory as your electrically heated glass door manufacturer, we need key information. Please supply:

- Quantity: Number of doors required.

- Dimensions: Width and height.

- Cooling temperature of your machine: e.g., +2 °C, –18 °C, etc.

- Ambient temperature & relative humidity: Typical environment where your unit will operate.

With those details, we can issue a professional quote including: production lead‑time, pricing (per unit and tooling if required), technical drawings, certification compliance, packaging & shipping plan. Let’s make your next refrigerated‑glass‑door project smooth, cost‑effective and technically flawless.

Conclusions

In summary: when you partner with the right electrically heated glass door manufacturer, you eliminate fogging, lift your product visibility, protect your schedule, and manage cost. We are ready to support you with in‑house control, rapid lead‑times, and full customisation. Let’s start today.