Are rising energy bills, condensation problems, and damaged cooler doors quietly hurting your beer cave performance and creating headaches for procurement teams?

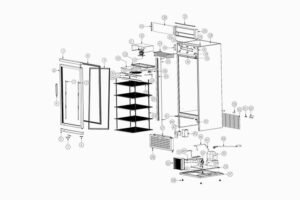

Beer cave doors are insulated glass or solid doors engineered for walk-in beer coolers, designed to maintain stable temperatures, reduce energy loss, and withstand heavy commercial traffic while improving product visibility.

Behind every efficient beer cave is a door system built specifically for cold environments and constant use. When the door is wrong, energy waste and maintenance costs follow.

Table of Contents

How Do Beer Cave Doors Work in Walk-In Cooler Systems?

Are standard walk-in cooler doors failing under frequent opening cycles, pallet movement, and customer traffic inside beer caves?

Beer cave doors combine insulated frames, Low-E heated glass, and heavy-duty hinges to keep beer caves at 0–4°C (32–39°F) while minimizing temperature fluctuation during frequent access.

Beer caves are different from back-of-house cold rooms. They are larger, accessed more often, and sometimes customer-facing, which changes how doors must perform.

Core Functional Principles

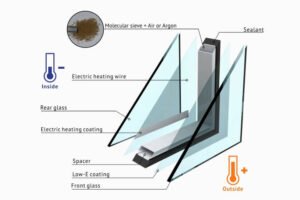

- Thermal insulation: Multi-pane insulated glass limits heat transfer.

- Condensation control: Low-E coatings and optional door heaters prevent fogging.

- Structural durability: Reinforced aluminum or steel frames resist impact from carts and kegs.

Typical Operating Conditions

| Parameter | Standard Range |

|---|---|

| Temperature | 0–4°C (32–39°F) |

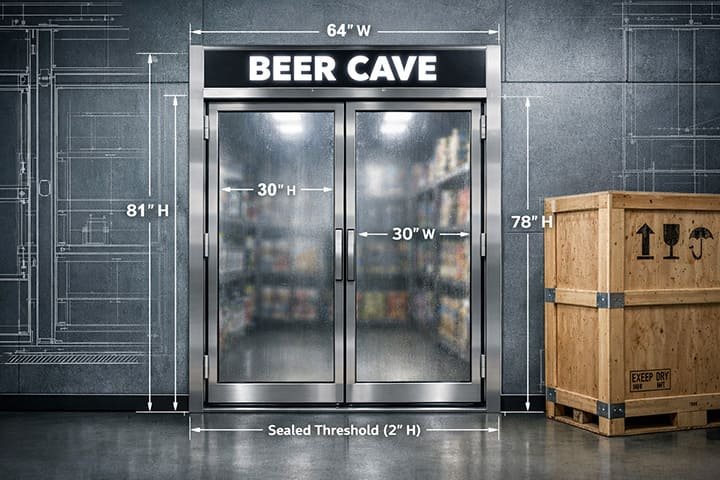

Door Size | 32″ × 81″ (812.8 × 2057.4 mm) 36″ × 81″ (914.4 × 2057.4 mm) 36″ × 84″ (914.4 × 2133.6 mm) |

| Opening Cycles | 1,000+ per day |

| Humidity | High |

These conditions demand doors engineered for both refrigeration efficiency and retail durability.

What Specifications Define High-Quality Beer Cave Doors?

Are you comparing quotes but unsure which technical details actually affect performance and lifetime cost?

High-quality beer cave doors are defined by insulated glass thickness, frame material, hinge load capacity, gasket sealing, and compliance with commercial refrigeration standards.

Experienced buyers focus on specifications that reduce failure risk and energy waste.

Key Technical Specifications

| Specification | Recommended Value |

|---|---|

| Glass Type | Double or triple-pane Low-E |

| Glass Thickness | 20–28 mm (0.8″–1.1″) |

| Frame Material | Aluminum alloy or stainless steel |

| Insulation | Foamed polyurethane |

| Gasket Type | Magnetic, replaceable |

| Hinge Load Rating | ≥120 kg (265 lb) |

Compliance and Standards

Well-engineered beer cave doors typically align with:

- U.S. Department of Energy commercial refrigeration efficiency guidance

See Source - NSF/ANSI sanitation standards for food retail environments

- UL safety requirements for heated glass and electrical components

Ignoring these factors often leads to air leakage, condensation complaints, and higher compressor runtime.

Manual vs Automatic Beer Cave Doors: Which Is Better?

Are automatic beer cave doors worth the investment, or do manual doors still make more sense for cost control?

Manual beer cave doors offer lower upfront cost and simplicity, while automatic doors improve traffic flow, reduce door-open time, and enhance customer experience in high-volume stores.

The right choice depends on store layout and usage intensity.

Comparison Overview

| Feature | Manual Doors | Automatic Doors |

|---|---|---|

| Initial Cost | Lower | Higher |

| Maintenance | Minimal | Motor & sensor servicing |

| Energy Control | Operator-dependent | Consistent |

| Customer Access | Slower | Faster |

| Cart & Pallet Traffic | Moderate | Excellent |

Automatic beer cave doors are increasingly adopted in supermarkets and warehouse clubs where speed and safety matter. They must comply with ANSI/BHMA automatic door safety standards:

See Source

How Do Beer Cave Doors Impact Energy Cost and Product Sales?

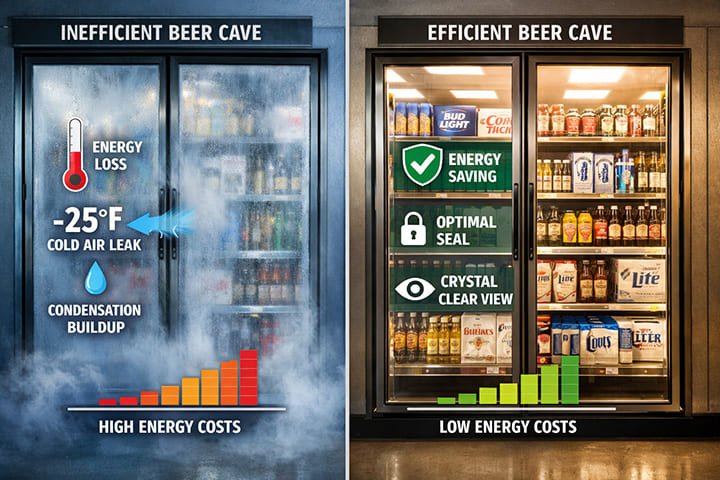

Are invisible air leaks and fogged glass quietly reducing profit margins?

Efficient beer cave doors can reduce cold air loss by up to 30%, stabilize refrigeration cycles, and increase product visibility—directly impacting energy cost and beverage sales.

Poor door performance forces refrigeration systems to work harder.

Energy Performance Drivers

- Tight gaskets limit air infiltration

- Insulated glass reduces radiant heat gain

- Self-closing hinges minimize door-open duration

ENERGY STAR emphasizes that door efficiency is a major factor in total operating cost for commercial refrigeration:

See Source

Sales Impact

Clear, fog-free glass improves:

- Product visibility

- Impulse purchasing

- Customer dwell time inside the beer cave

Beer caves are not just storage spaces—they are revenue-generating displays.

How Should You Choose a Reliable Beer Cave Door Manufacturer?

Are you confident your supplier understands both manufacturing precision and export-grade quality control?

A reliable beer cave door manufacturer offers customization, strict quality testing, international compliance support, and long-term spare part availability.

For procurement teams, supplier capability determines long-term risk.

Manufacturer Evaluation Checklist

| Criteria | Why It Matters |

|---|---|

| Custom Dimensions | Fits existing walk-in openings |

| In-house Testing | Verifies thermal performance |

| Export Experience | Ensures compliant packaging |

| MOQ Flexibility | Supports distributors |

| After-sales Support | Reduces downtime |

At PARTSAY, we design and manufacture beer cave doors for global B2B buyers, focusing on durability, energy efficiency, and total cost control.

Get A Quote

Easy steps to customize and order your perfect glass door.

STEP 1

B2B Partnerships Only

Please note that our focus is on B2B relationships. We exclusively supply our premium glass doors to businesses, not to individual consumers.

Our MOQ is 10 pieces.

STEP 2

To Tailor Your Order Precisely, We Require the Following Details:

Order Volume – Please specify the quantity of glass doors needed. Door Dimensions – Indicate the width and height measurements. Glass Configuration – Do you request 2-pane or 3-pane glass? Additional Specifications – Inform us of any specific requirements for frame materials (metal, aluminum, plastic, etc.) and glass types (tempered, low-E, heated, etc.). For optimal accuracy, kindly attach any technical drawings or blueprints of your desired glass doors.STEP 3

Reply within 2 Days

Upon receiving your specifications, we will provide a detailed cost estimate within 2 business days.

Conclusion

Beer cave doors directly influence energy efficiency, compliance, and sales performance. Choose engineered solutions, not generic doors. Contact PARTSAY to discuss export-ready beer cave door systems built for your market.