Struggling with high import costs, complex logistics, and inefficient assembly processes for your refrigeration equipment? You’re not alone. Many manufacturers face these challenges when sourcing parts and components. But there’s a solution: CKD and SKD kits. Let’s dive into these options and find out which suits your business best.

CKD (Completely Knocked Down) and SKD (Semi-Knocked Down) kits offer cost-effective and efficient ways to manage your refrigeration manufacturing. CKD involves shipping fully disassembled parts, while SKD kits come partially assembled. Both methods can significantly cut down costs and simplify logistics.

So, which one should you choose? Stick with me as we explore the ins and outs of CKD and SKD solutions and determine the best fit for your needs.

Table of Contents

What are CKD and SKD Kits?

CKD (Completely Knocked Down)

Definition: CKD kits involve disassembling a product into all its parts and shipping them for reassembly at the destination.

Benefits:

- Lower Import Duties: Importing parts is often cheaper than importing fully assembled units.

- Customization: Allows for specific customizations according to local market needs.

- Job Creation: Local assembly can create jobs, boosting the local economy.

SKD (Semi-Knocked Down)

Definition: SKD kits involve shipping products in partially assembled sub-assemblies.

Benefits:

- Simpler Assembly: Easier and quicker to assemble compared to CKD.

- Cost Savings: Reduces transportation costs and import duties.

- Less Complex Logistics: Fewer parts mean simpler logistics.

CKD & SKD Accessories Comparison List

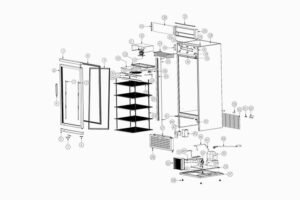

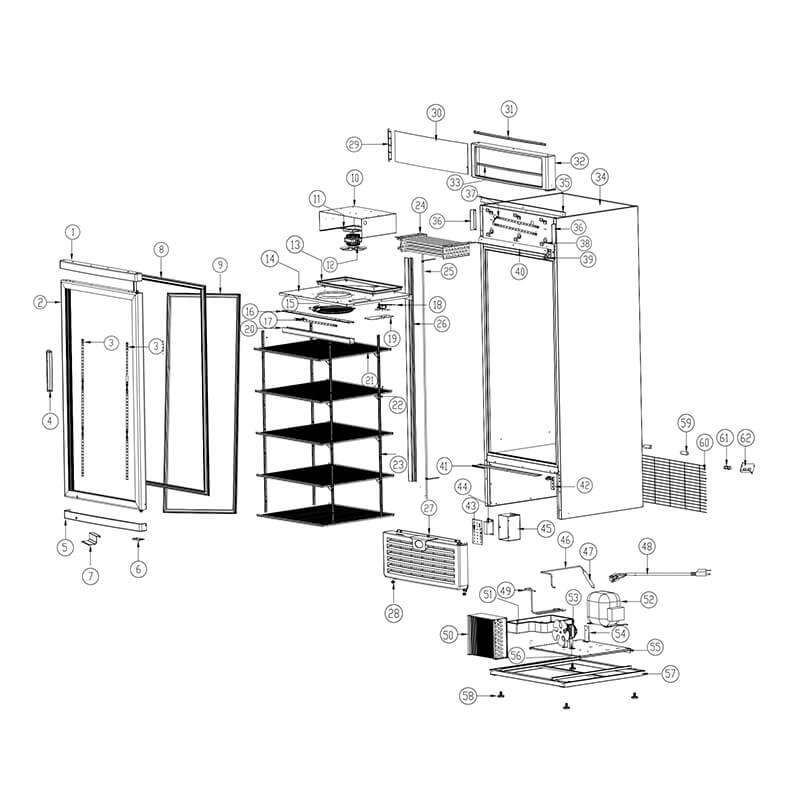

Let’s delve into the specifics of what constitutes CKD (Completely Knocked Down) and SKD (Semi-Knocked Down) forms for refrigeration parts. In CKD form, the refrigerator is completely disassembled into individual components. In SKD form, the refrigerator is partially assembled and usually shipped in larger sub-assemblies. Here are the specific parts typically included:

| Number | Refrigerator Parts | CKD (Completely Knocked Down) | SKD (Semi-Knocked Down) |

|---|---|---|---|

| 1 | Top Plastic Strip of Glass Door | Shipped separately | Pre-installed on door assembly |

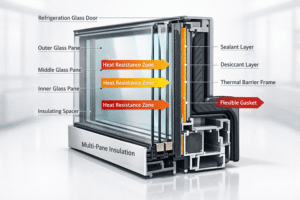

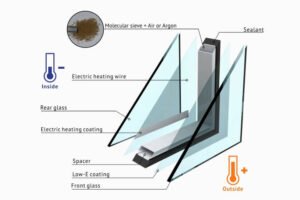

| 2 | Glass Door | Shipped as individual parts (frame, insulation, gasket) | Fully assembled with frame, hinge, handle and gasket |

| 3 | LED Light in the Glass Door | Shipped as individual fixtures | Pre-installed in door assembly |

| 4 | Door Handle | Shipped separately | Pre-installed on door |

| 5 | Low Plastic Strip of Glass Door | Shipped separately | Pre-installed on door assembly |

| 6 | Door Limiter | Shipped separately | Pre-installed on door |

| 7 | Door Support | Shipped separately | Pre-installed on door |

| 8 | LED Light Cover | Shipped separately | Pre-installed in door assembly |

| 9 | Door Gasket | Shipped separately | Pre-installed on door |

| 10 | Side Panel | Shipped separately | Pre-assembled in foam cabinet |

| 11 | Fan Support | Shipped separately | Pre-installed in fan unit |

| 12 | Evaporating Fan | Shipped separately | Pre-installed or as simple plug-and-play units |

| 13 | Water Container | Shipped separately | Pre-installed in assembly |

| 14 | Control Panel | Shipped as individual components | Pre-installed and pre-wired in the cabinet |

| 15 | Fan Guard | Shipped separately | Pre-installed in fan unit |

| 16 | Lamp Stand | Shipped separately | Pre-installed in assembly |

| 17 | LED Light | Shipped as individual fixtures | Pre-installed in assembly |

| 18 | Thermostat | Shipped as individual component | Pre-wired and installed in a sub-assembly |

| 19 | Thermostat Panel | Shipped separately | Pre-installed in assembly |

| 20 | LED Light Cover | Shipped separately | Pre-installed in assembly |

| 21 | Shelf | Shipped separately | Pre-installed or packaged together |

| 22 | Shelf Clips | Shipped separately | Pre-installed or packaged together |

| 23 | Pilasters | Shipped separately | Pre-installed or packaged together |

| 24 | Evaporator | Shipped separately | Pre-mounted and connected with refrigerant tubing |

| 25 | Return Pipe | Shipped as individual tubes | Included within sub-assemblies |

| 26 | Return Pipe Cover | Shipped separately | Pre-installed in assembly |

| 27 | Grill | Shipped separately | Pre-installed in assembly |

| 28 | Plastic Fixation Column | Shipped separately | Pre-installed in assembly |

| 29 | Inserts | Shipped separately | Pre-installed in assembly |

| 30 | Shipped separately | Pre-installed in assembly | |

| 31 | Top Strip Inside Light Canopy | Shipped separately | Pre-installed in assembly |

| 32 | Outline Border of Light Canopy | Shipped separately | Pre-installed in assembly |

| 33 | Low Strip Inside Light Canopy | Shipped separately | Pre-installed in assembly |

| 34 | Foam Cabinet | Shipped as separate exterior and interior panels, with insulation materials | Shipped as one whole insulated body |

| 35 | Top Frame of Light Canopy | Shipped separately | Pre-installed in assembly |

| 36 | Left and Right Support of Light Canopy | Shipped separately | Pre-installed in assembly |

| 37 | LED Light Inside Light Canopy | Shipped as individual fixtures | Pre-installed in assembly |

| 38 | Bracket for LED Light | Shipped separately | Pre-installed in assembly |

| 39 | Top Hinge | Shipped separately | Pre-installed on door assembly |

| 40 | Low Frame of Light Canopy | Shipped separately | Pre-installed in assembly |

| 41 | Fixing Bracket for Grill | Shipped separately | Pre-installed in assembly |

| 42 | Lower Hinge | Shipped separately | Pre-installed on door assembly |

| 43 | Electric Box Cover | Shipped separately | Pre-installed on door assembly |

| 44 | Transformer for LED Light | Shipped separately | Pre-installed and pre-wired in assembly |

| 45 | Electric Box | Shipped as individual components | Pre-installed and pre-wired in assembly |

| 46 | Connecting Tube for Dry Filter | Shipped as individual tubes | Included within sub-assemblies |

| 47 | Filter Dryer | Shipped separately | Pre-installed in assembly |

| 48 | Power Cord | Shipped as individual components | Pre-installed and pre-wired in assembly |

| 49 | Connecting Tube for Condenser | Shipped as individual tubes | Included within sub-assemblies |

| 50 | Condenser | Shipped separately | Pre-mounted and connected with refrigerant tubing |

| 51 | Water Container | Shipped separately | Pre-installed in assembly |

| 52 | Compressor | Shipped as an individual component | Part of a pre-assembled unit with wiring and connectors |

| 53 | Condenser Fan | Shipped separately | Pre-installed or as simple plug-and-play units |

| 54 | Filter Dryer Bracket | Shipped separately | Pre-installed in assembly |

| 55 | Upper Baseboard | Shipped separately | Pre-installed in assembly |

| 56 | Fan Support | Shipped separately | Pre-installed in fan unit |

| 57 | Lower Baseboard | Shipped separately | Pre-installed in assembly |

| 58 | Casters or Leveling Legs | Shipped separately | Attached or packaged with minimal assembly required |

| 59 | Bumper Block | Shipped separately | Pre-installed in assembly |

| 60 | Compressor Guard | Shipped separately | Pre-installed in assembly |

| 61 | Light Switch | Shipped separately | Pre-installed and pre-wired in assembly |

| 62 | Bracket for Light Switch | Shipped separately | Pre-installed in assembly |

How Do CKD and SKD Solutions Impact Your Bottom Line?

Cost Efficiency

- CKD: Offers the lowest import duties, making it a cost-effective choice for large-scale manufacturers.

- SKD: Balances cost and ease of assembly, making it suitable for medium-sized operations.

Customization and Flexibility

- CKD: Provides high flexibility for customization, catering to specific market demands.

- SKD: Offers moderate customization options with quicker assembly times.

Logistics and Assembly

- CKD: Requires comprehensive logistics management and skilled labor for assembly.

- SKD: Simplifies logistics with fewer parts and requires less assembly expertise.

Why Choose CKD Solutions for Your Refrigeration Equipment?

- Cost Reduction: CKD kits help significantly reduce import duties and transportation costs.

- High Customization: CKD allows for extensive customization to meet specific market needs.

- Local Job Creation: Creating local assembly jobs can boost your brand's reputation and support the local economy.

- Greater Control Over Quality: Assembling locally means you can monitor and ensure high-quality standards.

Why Choose SKD Solutions for Your Refrigeration Equipment?

- Simplified Assembly: SKD kits are easier and quicker to assemble, saving you time and labor costs.

- Balanced Cost and Efficiency: SKD offers a good balance between cost savings and ease of assembly.

- Streamlined Logistics: Fewer parts mean simpler logistics and reduced risk of missing components.

- Faster Time-to-Market: With quicker assembly, you can get your products to market faster, meeting demand efficiently.

How to Decide Between CKD and SKD?

Consider Your Market

- Customization Needs: Do your clients need highly customized products?

- Speed Requirements: How quickly do you need to get products to market?

Evaluate Your Resources

- Labor: Do you have skilled labor for assembly?

- Facilities: Do you have the space and tools for complete assembly?

Assess Costs

- Import Duties: Calculate potential savings on import duties.

- Logistics: Evaluate the complexity and cost of logistics for each option.

How to Implement CKD and SKD Solutions?

- Partner with Reliable Suppliers: Choose suppliers who offer high-quality parts and reliable delivery schedules.

- Train Your Workforce: Ensure your team is trained to handle the assembly processes efficiently.

- Invest in Quality Control: Set up robust quality control measures to maintain high standards.

- Streamline Logistics: Work with experienced logistics partners to manage the transportation of parts effectively.